The 2012 NFPA 70E, Standard for Electrical Safety in the Workplace, has been out for a while now. During the last revision cycle, the NFPA 70E committee received 548 proposals mostly (540 of them) from the public.

As a result, there were a number of new changes that occurred in the 2012 NFPA 70E version. Here is a brief description of some of the major changes:

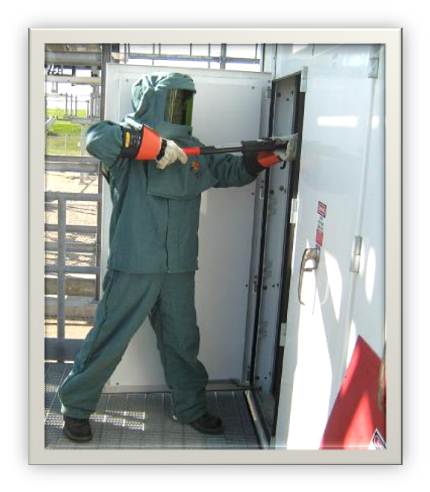

Arc-Rated (New): The 2012 edition of NFPA 70E will use the term “arc-rated” or “AR” before any reference to “flame-resistant” or “FR.” The term “arc-rated” refers to a material property or attribute in terms of a material’s performance when exposed to an electric arc. Arc-rated material is flame-resistant, but flame-resistant material may not be arc-rated.

Incident Energy Analysis (New Definition): The 2012 edition features a new informational note added to the existing arc flash hazard analysis definition. It defines the term “incident energy analysis” as “a method used to predict the incident energy of an arc flash for a specified set of conditions.”

Arc Flash Boundary (Revision): Previous editions referred to the arc flash protection boundary. The 2012 edition uses the term “arc flash boundary” (AFB). The word “protection” has been deleted.

Section 110.5(C) (New): This section is new to the code and requires a documented meeting between the host employer and contract employer for multiemployer relationships.

Section 110.6(C) Emergency Procedures (Revision): The 2012 edition requires the use of an automatic external defibrillator (AED) in addition to the existing requirement of training and employer certification of cardiopulmonary resuscitation (CPR). This is a great idea!

Section 110.6(D)(1)(f) (New): The language for this new section reads: “The employer shall determine through regular supervision and through inspections conducted on at least an annual basis that each employee is complying with the safety-related work practices required by this standard.” This mirrors similar language to the OSHA 29 CFR 1910.269(a)(2)(iii) standard.

Section 110.6(D)(3)(c) (Retraining) (New): The 2012 edition requires all employees to be retrained at intervals not to exceed three years.

Section 110.7(E) Electrical Safety Program Procedures (Revision): The 2012 edition incorporates language to include working within the AFB in addition to the existing requirement for working within the limited approach boundary (LAB). It is possible that the AFB could be greater than the LAB and vice versa.

Section 120.2(C)(2) (Form of Control) (Revision): The 2012 edition removes individual employee control as one of three forms of control of hazardous electrical energy, leaving the two methods: simple and complex lockout/tag out.

Section 130.1(A) General (Revision): The 2009 edition requires that energized conductors or circuit parts are placed into an electrically safe working condition before an employee works within the LAB. New language expands this requirement to apply if any of the following conditions exist:

- The employee is within the LAB (same as before)

- The employee is within the AFB

- The employee interacts with equipment where conductors or circuit parts are not exposed, but an increased risk of arc flash hazard exists

Table 130.2(C) Approach Boundaries to Energized Electrical Conductors or Circuit Parts for Shock Protection (Revision): The 2012 edition features a renumbered version of this table as Table 130.2(C)(1), and it will specifically apply to alternating current (AC) power systems. A new table, 130.2(C)(2) applies to direct current (DC) power systems.

Section 130.3 Exception No. 1 (Revision): This exception is based on language found in Institute of Electrical and Electronics Engineers (IEEE) Std. 1584—Guide for Performing Arc-Flash Hazard Calculations. Exception 1 stated that an arc flash hazard analysis shall not be required on circuits rated 240 volts (V) or less and supplied by one transformer if the transformer is less than 125 kilovolt-amperes. This exception has been deleted. In its place, an informational note will state that an arc flash hazard analysis may not be necessary for some three-phase systems rated less than 240V. It will then reference the IEEE standard for more information.

Section 130.3(A) Arc Flash Boundary (Revision): The 2012 edition will not feature the “four foot rule” in this section, and there will no longer be separate sections for the AFB at voltage levels between 50V and 600V and voltage levels above 600V. The revised language will state that the AFB for systems 50V and greater shall be the distance at which the incident energy is 1.2 calories per square centimeter. Instead of the “four foot rule,” AFB will be located in Table 130.7(C)(9). This is an important one!

Section 130.3(C) Equipment Labeling (Revision): This section provides more guidance on what equipment needs labeling based on language similar to the 2011 NEC. Electrical equipment—such as switchboards, panel boards, industrial control panels, meter socket enclosures and motor control centers—and that are likely to require examination, adjustment, servicing or maintenance while energized, shall be field-marked with a label containing all of the following information:

(1) Only one of the following:

a. Available incident energy

b. Minimum arc rating of clothing

(2) Date of arc flash hazard analysis

(3) Nominal system voltage

(4) Equipment identification

(5) Arc flash boundary

Section 130.7(C)(X) (Hearing Protection) (New): Employees shall wear hearing protection whenever working within the AFB. Previous editions only listed hearing protection in Table 130.7(C)(10) Protective Clothing and Personal Protective Equipment and did not address it specifically. The new language clarifies when hearing protection is required as well as the appropriate requirements for that protection.

Category 2* Deleted (Revision): Category 2 will require a balaclava sock or an arc flash suit hood. There was an inconsistency with Section 130.7(C)(1), which required all parts of the body inside the AFB to be protected. This is an important one!

Section 130.7(C)(13)(a) (Arc Flash Suits) (Revision): Additional language state: “When the incident energy exposure is greater than 12 cal/cm2, a suitably rated arc flash suit hood shall be used.”

Section 130.7(C)(13)(b) (Face Protection) (Revision): The 2012 edition features new language in this section, requiring face shields with a wraparound guarding to protect the face, chin, forehead, ears and neck to be used.

Summary:

The 2012 edition of NFPA 70E established many positive changes and I only covered some of the major ones. To learn about the new standard and how to become a qualified worker take our NFPA 70E class. https://safetylinks.net/index.php/training/safety-courses-for-all-industries/arc-flash.

Continue Reading

Some of the types of organizations OSHA and NIOSH have stated they plan to work with are trade associations, labor unions, employers, universities, community and faith-based organizations, and consulates.

Some of the types of organizations OSHA and NIOSH have stated they plan to work with are trade associations, labor unions, employers, universities, community and faith-based organizations, and consulates.