Chemical Safety In The Workplace

The inherent hazards of chemicals can be reduced by minimizing the quantity of chemicals on hand. However, when chemicals must be used, proper storage and handling can reduce or eliminate associated risks.

Proper storage information can usually be obtained from the Safety Data Sheet (SDS), label or other chemical reference material. As required by OSHA, a SDS must be on hand for every chemical in your workplace. The SDS and chemical label can be consulted for information on special storage requirements. The SDS can also answer questions such as:

- Is the chemical a flammable or combustible?

- Is the chemical a corrosive?

- Does the chemical need to be stored other than at ambient temperature?

- Is the chemical an oxidizer or reducer?

- Is the chemical light sensitive?

- Does the chemical require any special handling procedures?

Typical storage considerations may include temperature, ignition control, ventilation, segregation and identification. Proper segregation is necessary to prevent incompatible materials from inadvertently coming into contact. If incompatible materials were to come into contact, fire, explosion, violent reactions or toxic gases could result. When segregating chemicals, acids should not be stored with bases, and oxidizers should not be stored with organic materials or reducing agents. A physical barrier and/or distance is effective for proper segregation.

If cabinets are used to segregate chemicals, consider the compatibility of the chemicals with the cabinet. For example, corrosives, like strong acids and caustics, will corrode most metal cabinets. Non-metallic or epoxy-painted cabinets are available and will provide a better service life with these types of chemicals. However, it is recommended that hydrochloric acid not be stored in any metal cabinet. Some other acids and bases may damage the painted surfaces of a cabinet if a spill occurs.

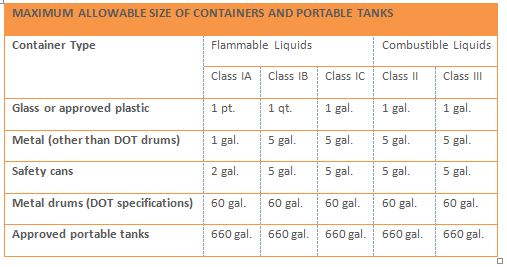

There are cabinets available specifically for flammable and combustible materials. It is important to be aware of maximum allowable container size and maximum quantities for storage in cabinets based on the class of the flammable. The class of a flammable or combustible is determined by its flash point and boiling point.

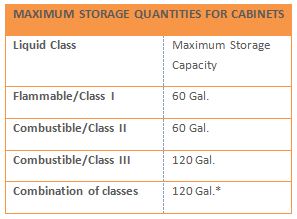

The following chart lists the maximum volume of flammables and combustibles that can be stored in a single flammable storage cabinet.

*Not more than 60 gallons may be Class I and Class II liquids. No more than 120 gallons of Class III liquids may be stored in a storage cabinet, according to OSHA 29 CFR 1910.106(d)(3) and NFPA 30 Section 4-3.1.

NOTE: Not more than three such cabinets may be located in a single fire area, according to NFPA 30 Section 4-3.1.

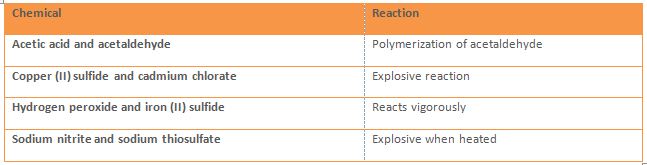

One more thing…..Do Not Store Chemicals Alphabetically

For ease of locating chemicals, many storerooms organize chemicals alphabetically. However, chemical storage based upon an alphabetical arrangement of chemicals may inadvertently locate incompatible materials in close proximity. A few examples of this potentially dangerous storage method are demonstrated by the following pairs of incompatible materials:

If you want more information on chemical storage assessments or GHS/HazCom training contact Randy Free. 407-353-8165 or email him at rfree[at]safetylinks.net

Smoke alarms will detect most fires more rapidly than heat detectors. There are currently three types of smoke alarms on the market: ionization, photoelectric and combination ionization/photoelectric.

Smoke alarms will detect most fires more rapidly than heat detectors. There are currently three types of smoke alarms on the market: ionization, photoelectric and combination ionization/photoelectric.