Confined spaces are a huge issue for many of our Safety Partners. OSHA regulates permit-required confined spaces in 29 CFR 1910.146. If you have ever had a chance to read this regulation, you will know it is riddled with technical language that even the most experienced employee would have trouble grasping.

For that reason you must make every attempt to simplify the information so that your employees can most effectively understand the specific requirements of each confined space they may enter. One of the best methods to achieve this is by developing a Confined Space Hazard Assessment and Control Program and training your staff on how to use it!

What is a confined space?

Before we start to discuss the Hazard Assessment and Control Program, we must first understand what a confined space is. A confined space is defined as any space that is:

- large enough and so configured that a person can bodily enter and perform assigned work

- has limited or restricted means for entry or exit (example: tanks, vessels, silos, storage bins, hoppers, vaults, and pits, etc.)

- isn’t designed for continuous worker occupancy.

What is the best way to develop a confined Space Hazard Assessment and Control Program?

Properly assessing your confined space hazards will allow you to also identify the required countermeasures that your employees will require. A Confined Space Hazard Assessment and Control Program, specific for the work being conducted, should be written for work in each of your confined spaces.

The program should include the following:

- Advice on how to identify confined spaces

- The identification and assessment of all potential hazards that may exist at the beginning of the work, as well as those that may develop because of the work activities

- A plan to eliminate or control all identified hazards

- Training program for all the workers that will enter into the confined spaces

- The establishment of an entry permit system for each entry into a confined space

- Development of an emergency plan complete with training and equipment in case an unforeseen situation occurs

- An emergency response system

- Program review whenever there is a change in circumstances or at least annually, to identify program weaknesses and make any necessary changes to the program

Is Confined Space training important?

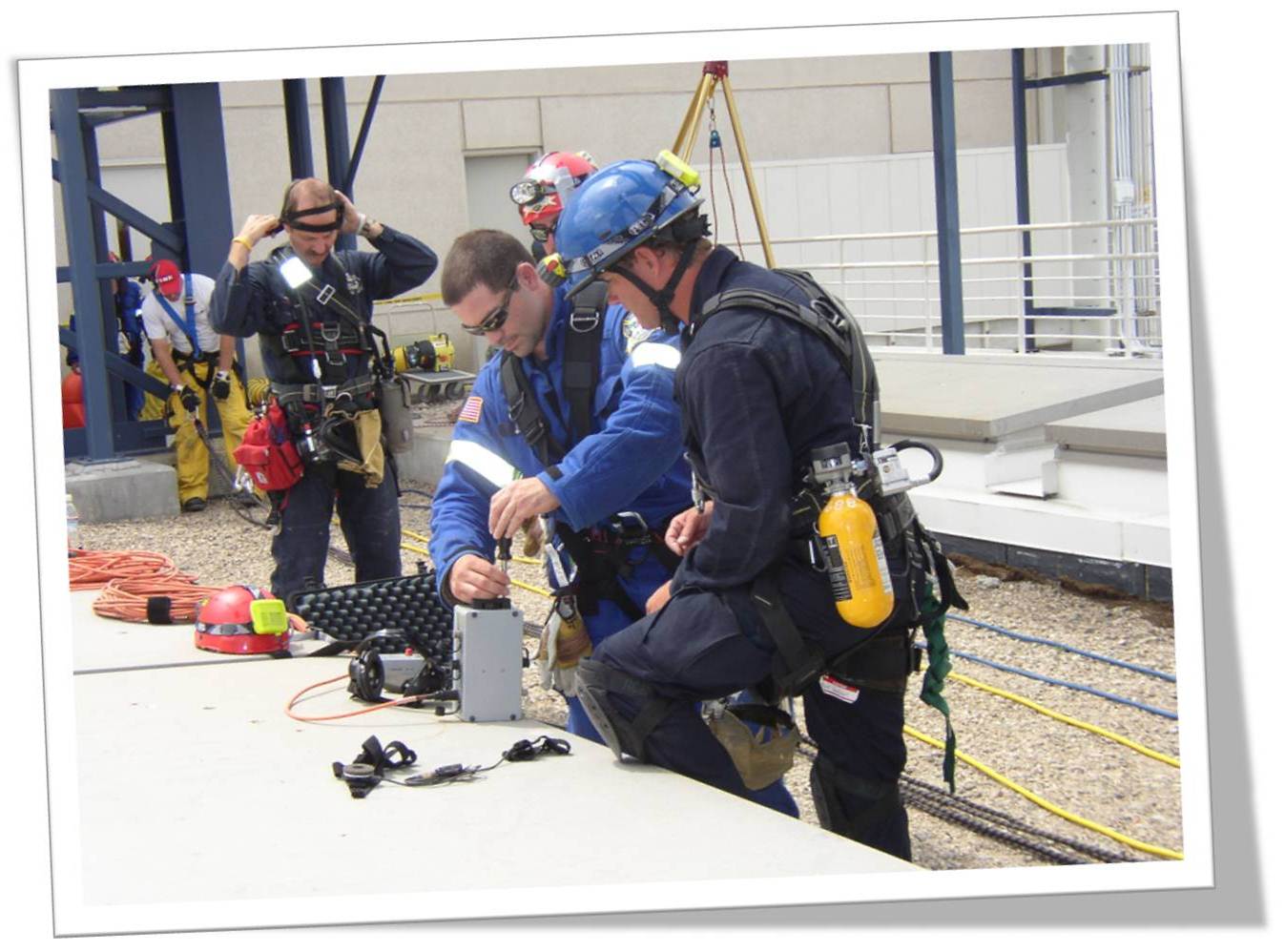

Yes, appropriate training is extremely important to working safely in confined spaces. Hands-on training should be an essential part of the confined space training.

Every worker that enters a confined space must be fully trained on the following:

- Recognition and identification of potential hazards associated with the confined spaces that will be entered.

- Evaluation and control procedures for the identified or potential hazards.

- All equipment such as ventilation equipment (blowers), harnesses and air quality monitors (e.g., Oxygen/combustible meters) that will be used while in the confined space.

- All personal protective equipment (e.g., respirators) that the worker will be using while in the confined space.

- All procedures for entering the confined space as outlined in the employer’s Confined Space Hazard Assessment Program.

- Procedures to follow in the event of a situation developing that could present additional risk to the worker or an emergency.

- The specific work to be done while in the confined space.

Workers with emergency rescue responsibilities will need additional specialized training. All confined space training should include some hands-on training with the safety equipment including the personal protective equipment and safety harnesses. Rescue procedures should be practiced frequently so there is a high level of proficiency.

If you need more information on confined space safety, including consulting or training please contact us at 1.800.768.7036.